Moldex3D IC Packaging Overview

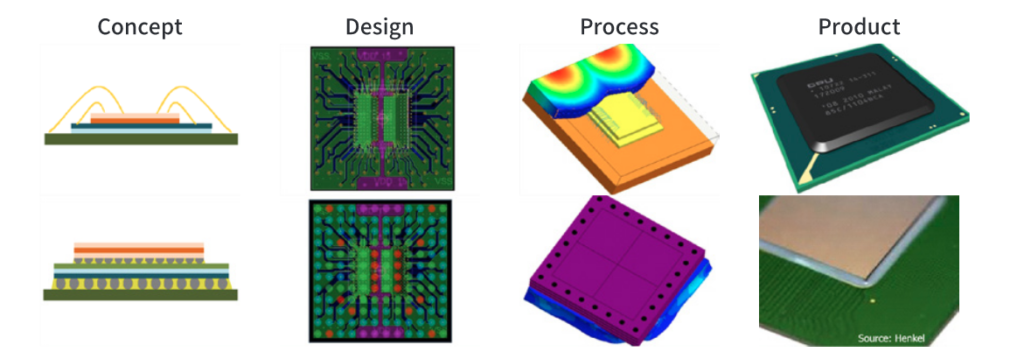

Plastic Chip Encapsulation is a molding process where chips are being capsulated with Epoxy Molding Compound (EMC) to prevent physical damage or corrosion. This process contains the interconnection between microchips and other electronics (so-called wire bonding), curing phenomenon of thermoset material, and various control management of process conditions. Due to the complexity of multiple material components, such as EMC, chip, or leadframe, and high wire density, many challenges and uncertainty have been brought to the Chip Encapsulation process. Common defects include incomplete fill, air traps, voids, wire sweep, paddle shift, package warpage, etc.

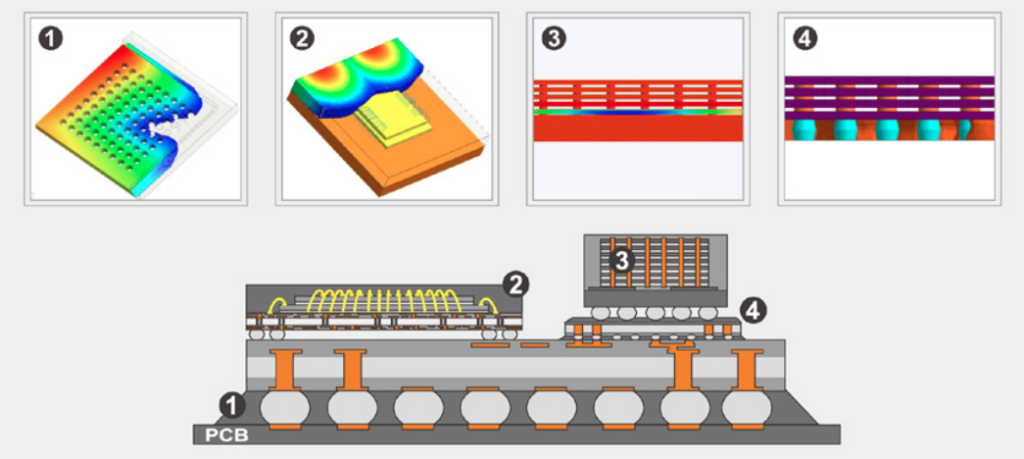

Moldex3D IC Packaging provides a complete series of molding solutions, and supports comprehensive solutions such as : Transfer Molding, Molded Underfill, Capillary Underfill (CUF), Compression Molding, Embedded Wafer Level Package (EMWLP), and No Flow Underfill (NFU) / Non Conductive Paste (NCP). Auto meshing function supports for user to complete encapsulation analysis more easily. User also can adopt advanced manual meshing for more complex component like undercut-shaped lead frame.

Moldex3D IC Packaging helps designers to fully analyze the chip encapsulation process from filling, curing, cooling, to advanced manufacturing demands, such as filler concentration, underfill encapsulation, post-molding curing, stress distribution, or structural evaluation. Significant molding problems can be predicted and solved upfront, which helps engineers enhance chip quality and prevent potential defects more efficiently. The accurate simulation also helps design optimization and well cost management. lead frame.

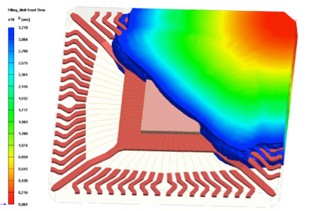

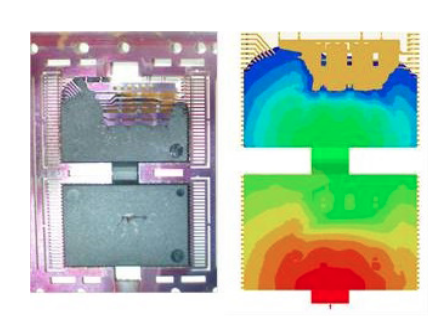

Melt front result in mold

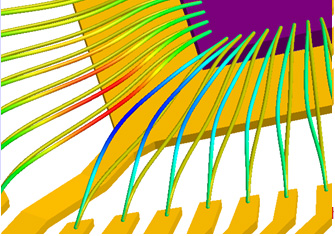

In Wire Sweep Analysis, deformed wires are compared with original wires based on the wire sweep

Product Portfolio and Features

● Essential features contained ○ Optional features

| Standard Package | |

|---|---|

| Solver Capabilities |

|

| Parallel Processing | 8 |

| Transfer Molding | ● |

| Simulation Capabilities | |

| Flow | ● |

| Cure | ● |

| Warp | ● |

| Thermal | ● |

| Stress | ● |

| Wire Sweep | ● |

| Paddle Shift | ● |

| Pre/Post Processors | |

| Mesh | ● |

| Auto-hybrid | ○ |

| Cadence Interface | ○ |

| Designer | ● |

| Project | ● |

| FEA Interface | ● |

| Molding Process | |

|---|---|

| Compression Molding (CM) |

|

| Compression Molding | ○ |

| No Flow Under Fill (NUF) | ○ |

| Embedded Wafer Level Package (EWLP) | ○ |

| Underfill | |

| Capillary Under Fill (CUF) | ○ |

| Molded Underfill (MUF) | ○ |

| Potting | |

| Potting | ○ |

| Post Mold Cure (PMC) | |

| Chemical shrinkage of material | ○ |

| Viscoelasticity stress relaxation | ○ |

| Material Test | |

|---|---|

| General Molding Process 1 | |

| Viscosity (Rheometer) | ○ |

| Curing Kinetics (DSC) | ○ |

| Special Molding Process 2 | |

| Specific Volume (PVTC) | ○ |

| Visco-elastics Modulus (DMA) | ○ |

| Contact Angle | ○ |

System Requirements

A. Supported Platform

| Platform | OS |

|---|---|

| Windows | Windows 10, Windows 8, Windows 7, Server 2019, Server 2016, Server 2012 R2 |

B. Hardware Recommendation

| Minimum | |

|---|---|

| CPU | Intel® Core i7 Sandy Bridge series processor |

| RAM | 16 GB RAM, and at least 1 TB free space |

| Recommended | |

| CPU | Intel Xeon Platinum 8000 series processor |

| RAM | 64 GB RAM & 4 TB free space HDD, NVIDIA Quadro & AMD Radeon series graphic card and 1920 x 1080 screen resolution |

Link – www.moldex3d.com